Client QBuild

Location Gerler Road, Hendra

Budget $8.6M

Timeline 24 weeks

Project Size 1226 sqm

Architect GHD Woodhead

Photography Alanna McTiernan

Premis was engaged by QBuild, under a traditional Lump Sum contract, to deliver a project for Queensland Museum Network (QMN). The project involved the refurbishment of an existing warehouse and a two-storey extension, providing additional storage and an environment-controlled facility for analysing & sorting artefacts.

More than 130,000 scientific specimens stored in ethanol from the Queensland Museum at Southbank, have been transferred to the modern, purpose-built facility at Hendra. The completed facility now houses the growing collection and provides bespoke laboratory facilities and office accommodation for Queensland Museum Network scientists and visiting researchers.

Scope

The project was highly technical and in addition to the construction of a new two-storey extension and refurbishment to an existing warehouse, a complete services infrastructure upgrade was required, including the installation of a new transformer and back up generator.

The new annex extension houses office accommodation, a specialised laboratory and handling facilities, for the maintenance of the collections and research purposes on the ground floor, and a full mechanical plant room with fire suppression equipment on level two.

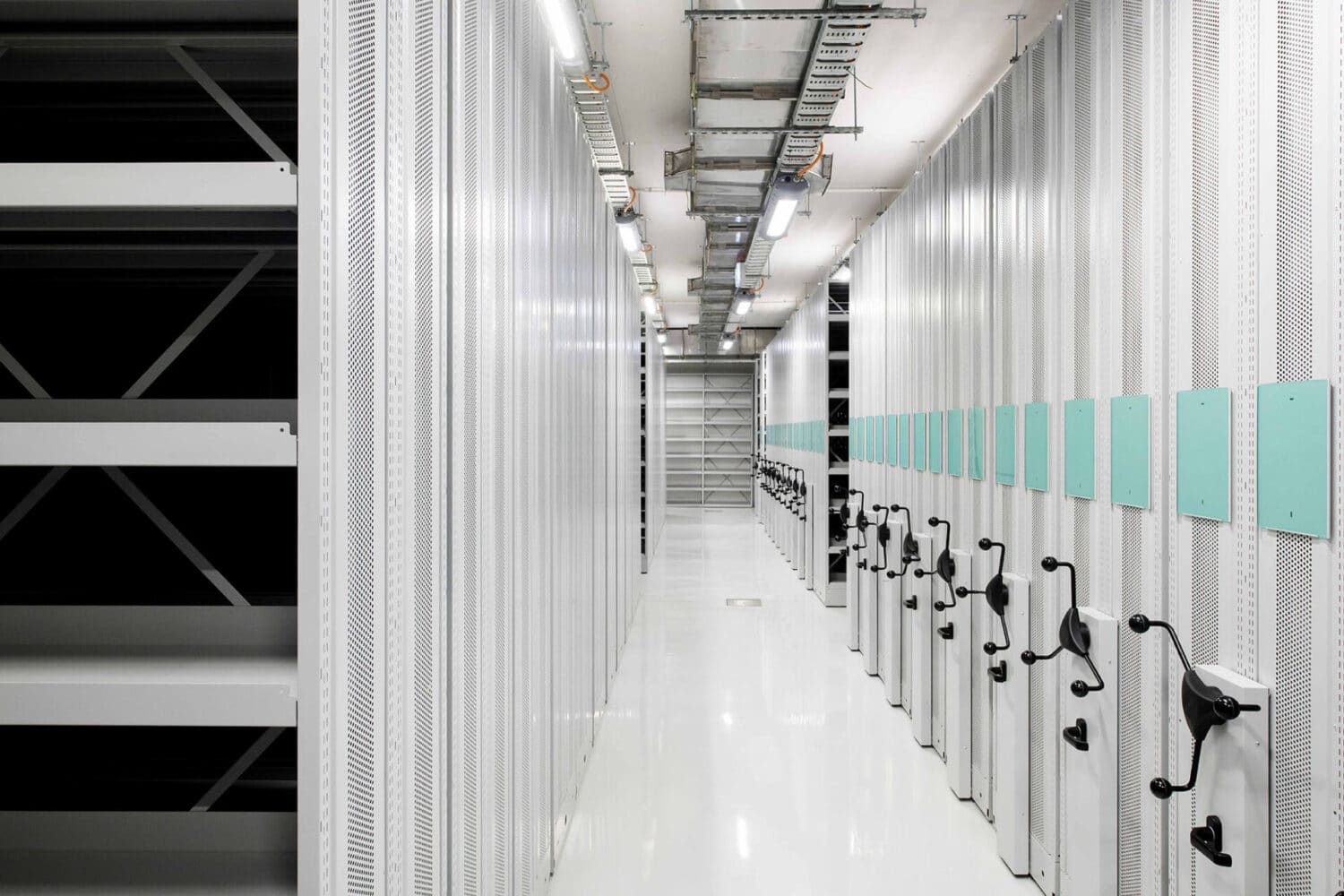

A key component of the build was a $1.1m specialised compactus storage system. The system, sourced from Austria, is state of the art and arguably the best in the world, featuring a frictionless rolling system. Prior to installation the floor required levelling and an earthing system to prevent any potential for sparking.

The facility required a relative humidity level of 50% and a temperature of 22 degrees to be maintained and has three labs including dirty lab, clean lab and formalin lab. Fume cupboards and nederman arms were installed in each of the lab. There is also a dedicated room housing a Scanning Electron Microscope (SEM) used for imaging minerals and other geological, biological, and environmental materials at the micrometer scale. SEMs require exceptionally stable room environments – to obtain atomic resolution images, the level of vibration, temperature fluctuations, electromagnetic waves, and acoustic waves must be limited. As such state-of-the-art vibration proof benches were installed.

The refurbishment of the existing warehouse required the construction of an internal shell with a fire suppression system to ensure the integrity of the collection.

The exterior of the building was cladded in Colourbond and custom-made aluminium two stage louvers that provide natural ventilation whilst still keeping all equipment protected from the elements. The mechanical plant, on level two, involved complex works including:

- Chiller system and associated air handling units

- Building Management System

- Mechanical services switchboards

- Hazardous area fume cupboard and extraction system

- Bench top fume exhaust system

- Formalin tank exhaust system.

Access Coordination

Emergency evacuation doors needed to be always active. There were three areas of access being the west, east and front. Most of the time staff entered from the front which left us both the east and the west for deliveries and trades movement. A project of this scale and complexity was bound to throw up some challenges. Our team worked in a collaborative way with the client and design team to deliver on the required outcome.